Our Spot Annealing Machine, using the Most Advance technology from Germany.

To be strictly control the temper of copper tube and its technical specification.

Level Wound Coil (Plain) Copper Tube

LEVEL WOUND COILED COPPER TUBE

│Copper tubes in Level-wound coils

Seamless copper tubes in level-wound coils (LWC)are particularly cost-effective for the manufacturer of heat exchangers, tube bends,fittings,heaters.Long lengths provides the consumer with two advantages:little scrap and long machine times.

│Material Copper tubes in Level-wound coils

Type DHP(material No.CW024A as per EN 12449,UNS No.C12200) copper.

This material meets the requirements of ASTM (B280,B68 and B75) and EN (12735-1,737-3 and 793) specifications.

● Temper

Soft annealed and hard as drawn .

◆Annealed tubes are supplied to manufacturer products where they must be formed to a high degree and where fittings and bends demand.

◆Hard temper copper tubes are normally used in the manufacturer of solar heat absobers,ect.

● Packing

Nominal weight standard for AGS level-wound coils are 100kg to 120kg.

RETA furnishes level wound coils with cardboard reels.

The reels are constructed of corrugated fiberboard and the reeled coils are palletized for ease in shipment and customer storage.

LWCs are wrapped in plastic film.

A wood pallet is provided.

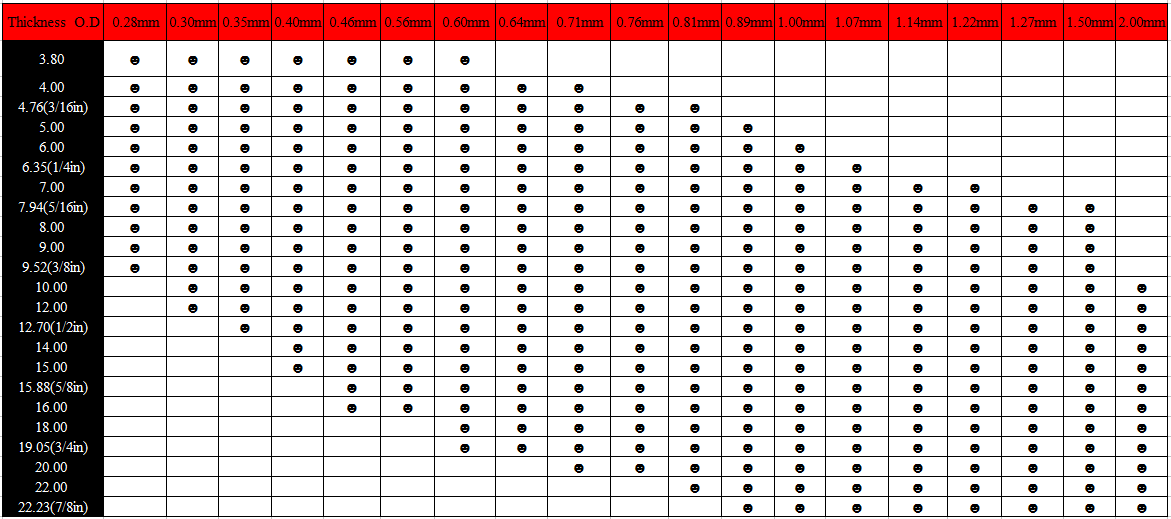

● Size Available

LWCs produced in the following size range:

Remark:Size with mark"☻"indicate those are common size with the company is making,Any unusual sizes with special requirement can be tailor-made against order.

| Option:TBLU | Tube: | Number: | Length: | Number: | Type: |

| TBLU: Hairpin bender | Max process tube dia.(mm): 1.5: φ5mm 2.7: φ7mm …… 3.15.88: φ15.88mm | Number of tube: process at one time 1.4: 4(tubes) 2.6: 6(tubes) 3.7: 7(tubes) 4.8: 8(tubes) 5.6+6: 12(tubes) | Max process tube length: 1.1300mm 2.2500mm …… 3.4500mm | number of centres: 1.M1:single die 2.M2:double dies | Decoiler type E:with motorized decoiler Q:with eye-to-sky decoiler |

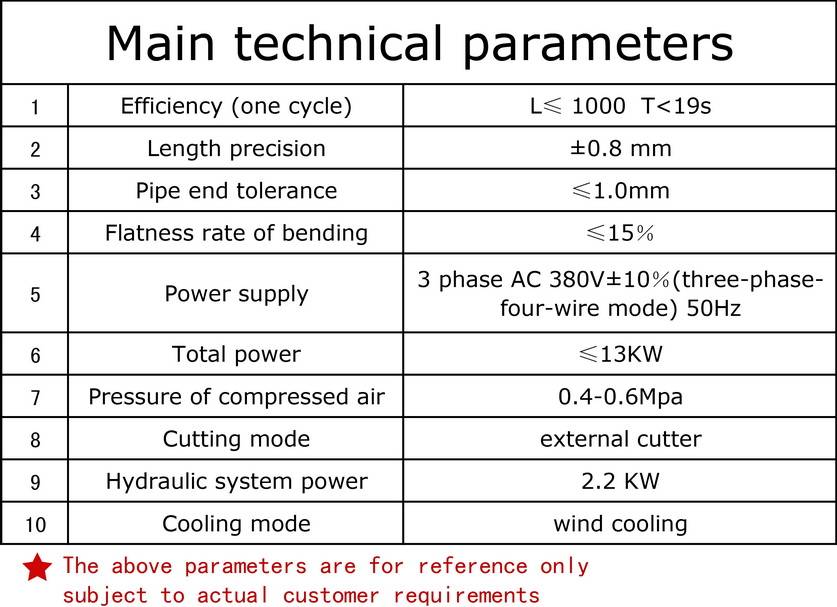

Purpose:

The Long U Hairpin Bender is used to Open, Straighten, Chipless Cut and bend Coil Copper Pipe into set length U shape pipe which is also called Hairpin Pipe; Mainly applied to the auto production of Long U pipe in Air-Condition Condensers and Evaporators.

Features:

1.Strippers, Frame move and Bend by Servo Moto.

2.Driven by frequency conversion moto and feed by belts.

3.Cutter Motor is driven by transducer, and the speed can be adjusted.

Reta Machinery are currently the leading manufacturer of machinery for both the mechanically expanded and brazed micro channel heat exchanger industry, globally. Our goals and long-term commitment is to constantly evolve our heat exchanger equipment, using research and development skills and vast production capacity. We operate in all areas of Air Conditioning, Radiator,Heater Core,Charge Air Coolers,Condensers, Evaporators for Truck and Car, Complex range of Fin Machines, Fin Presses,Core Builders, Tube Hairpin Benders, Vertical Expander, Horizontal Expander, Straight tube cut off, High Speed cut off, Return Benders, Ring Loading, Full range of mechanical presser. We have a stringent quality control system and all non-standard machine part is processed by ourselves.

RETA MACHINE CO.,LTD

Add: #99, Daqing South Road,

Jiangbei District, Ningbo,China.

Tel: +86-574-81106661

Email: info@retamachine.com

Web:www.retamachine.com

English

English Español

Español русский

русский